The aviation industry plays a vital role in the contemporary globalised environment, encompassing all passenger, cargo, and military aircraft. An estimated 100,000 flights are operated per day, worldwide, according to OAG Aviation. This necessitates a discussion on the emissions associated with conventional jet fuel consumption. While traditional jet fuel powers these operations, it contributes significantly to lifecycle greenhouse gas emissions. Sustainable Aviation Fuel (SAF), a fuel generated from alternative sources, offers a potential solution by reducing lifecycle greenhouse gas emissions by up to 80% compared to conventional jet fuel.

An Airbus A310-300 of Czech Airlines at 2010, Prague Václav Havel Airport.

Understanding Jet Fuel

Jet fuel is the third most important transportation fuel, derived from crude oil. Similar to kerosene, it offers a high energy density for long-haul flights. Despite this, jet fuel’s combustion releases a significant amount of greenhouse gases- the majority of which is carbon dioxide (CO2), a major contributor to climate change.

Conventional jet fuel is a chemically intricate blend of C9-C16 hydrocarbons. These hydrocarbons predominantly comprise n-paraffins, iso-paraffins, cycloparaffins, and aromatic compounds.

For commercial aviation, Jet A and Jet A-1 are the most commonly used fuels, which are produced to a standardized international specification. Jet A finds primary application within the continental United States, while Jet A-1 is the prevalent choice for the remainder of the globe. The only other jet fuel commonly used in civilian turbine-engine-powered aviation is Jet B, which is used for its enhanced cold-weather performance.

JP-5 (jet propellant-5) and JP-8 (jet propellant-8) fuels are used in military aircraft. Although JP-5, JP-8, and Jet A fuels share a common hydrocarbon base. Their key differences lie in the incorporation of specific additives. JP-8 contains a corrosion inhibitor and anti-icing additive absent in Jet A-1. Furthermore, JP-5 exhibits a higher flash point compared to JP-8.

F-15C Eagles from the 67th Fighter Squadron at Kadena Air Base, Japan, refuelled by a KC-135 Stratotanker from the 909th Air Refueling Squadron during joint bilateral training with other U.S. forces and the Japan Air Self Defense Force Feb 25, 2010.

Beyond Jet Fuel: SAF’s Recipe for a Brighter Future

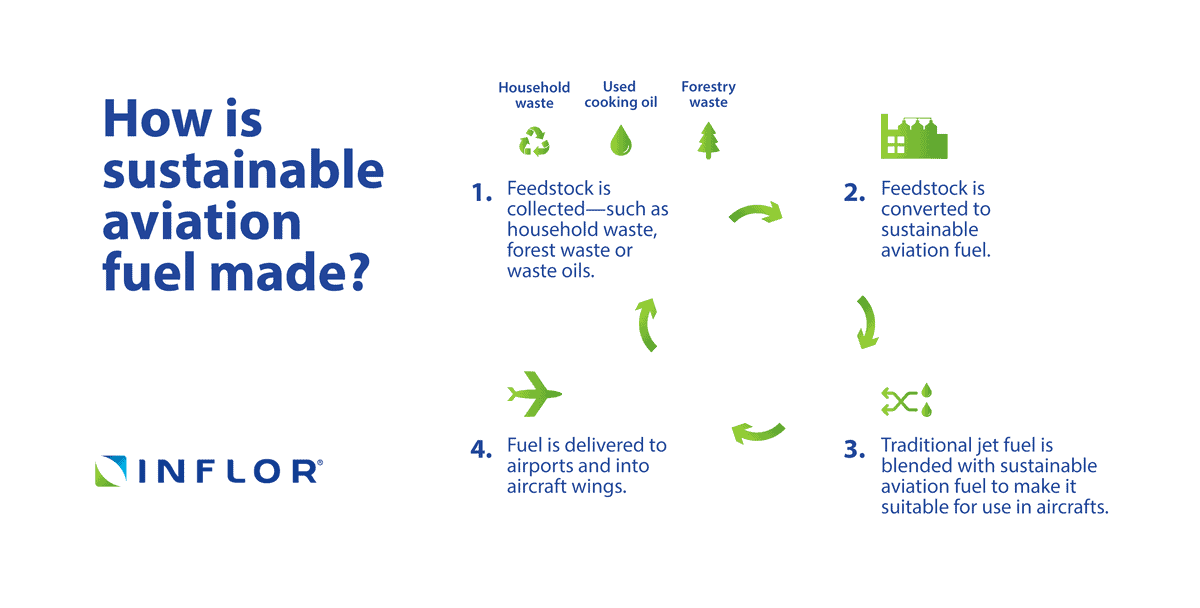

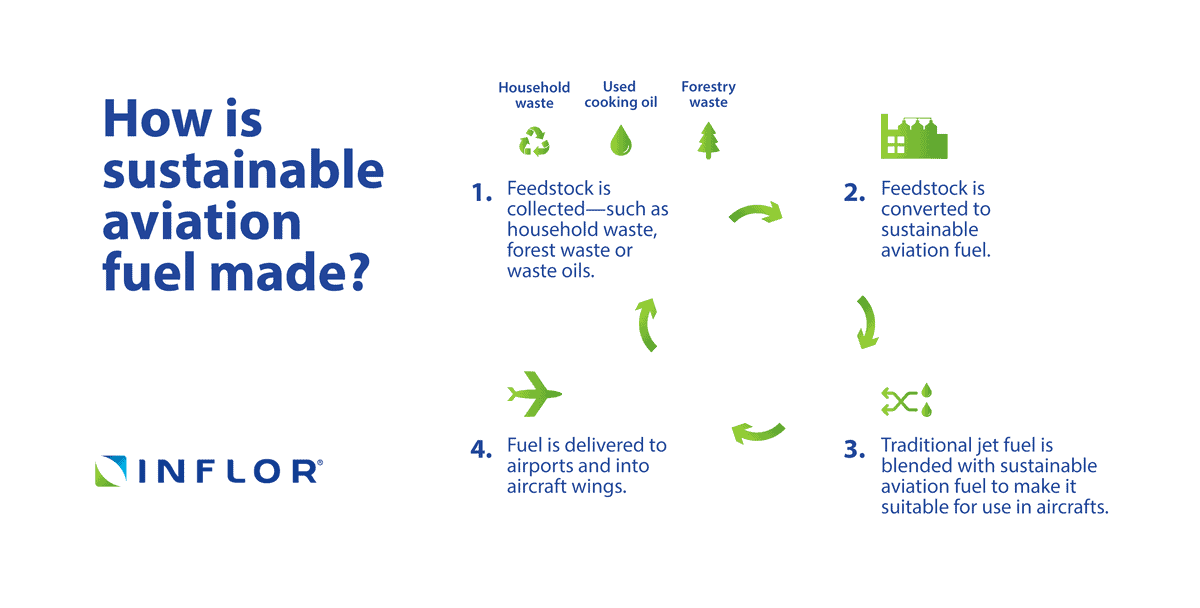

On the contrary, the production of Sustainable Air Fuel (SAF), has made leaps to reduce emissions due to combustion. SAF is a next-generation aviation fuel formulated with reduced lifecycle greenhouse gas emissions, derived from sustainable feedstocks, like used cooking oil, plant oils, and municipal waste. The primary sources of readily available biofeedstock for SAF production are fats, oils, and greases (FOGs). These offer a dual advantage: suitability for conversion into aviation fuel and renewable diesel for ground transportation. These feedstocks are processed using different technological pathways, such as Hydro-processed Esters and Fatty Acids (HEFA), Fischer-Tropsch (FT) synthesis and Alcohol to Jet (ATJ) conversion. Referred to as “drop-in fuel”, SAF resembles conventional jet fuels in chemical and physical characteristics. This allows SAF to be blended with traditional fuel without modifying existing aircraft or fueling infrastructure.

U.S. national labs explore promising avenues for next-generation SAF. The National Renewable Energy Laboratory (NREL) utilizes readily available wet waste to create carbon-negative SAF. Los Alamos National Laboratory (LANL) investigates bio-based SAF with 12% higher energy density than conventional fuel. Pacific Northwest National Laboratory (PNNL) captures waste carbon monoxide and converts it to ethanol for “alcohol-to-jet” SAF production.

According to the International Civil Aviation Organization (ICAO), over 360,000 commercial flights have used SAF at 46 airports, mainly in the US and Europe until 2022. Global aviation contributes 2% of CO2 emissions and 12% of transportation-related emissions. ICAO’s Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) aims to cap net CO2 emissions from aviation at 2020 levels until 2035. The industry targets net zero carbon emissions by 2050, with SAF identified as the primary short-term solution. The Sustainable Aviation Fuel Grand Challenge aims to increase domestic SAF consumption to 3 billion gallons by 2030 and 35 billion gallons by 2050, to reduce lifecycle greenhouse gas emissions by 50%.

Key Considerations for SAF

For a fuel to be considered truly sustainable, it must meet stringent criteria throughout its life cycle. This includes minimizing greenhouse gas emissions from its creation and use. Additionally, the production process shouldn’t require significant quantities of fresh water, a precious resource. Furthermore, the fuel source should avoid competing with food production for land, avoiding the social and environmental concerns associated with earlier biofuels. Also, sustainable fuel production should not contribute to deforestation, protecting valuable ecosystems and biodiversity. By meeting these critical requirements, fuel can be considered a sustainable solution for the future.

How Beneficial can SAF be?

The use of SAF demonstrably reduces lifecycle greenhouse gas emissions, particularly carbon dioxide. Compared to conventional jet fuel, SAF combustion generates lower emissions of pollutants like sulfur oxides and particulate matter, contributing to cleaner air around airports and flight paths. Furthermore, SAF combustion results in reduced emissions of harmful sulfur and nitrogen oxides, recognized as significant threats to human health and ecological stability.

SAF tackles aviation’s environmental impacts through three key features. First, it prioritizes sustainability by utilizing alternative feedstocks like organic wastes, reducing reliance on traditional crude oil. These feedstocks are processed differently than conventional jet fuel, minimizing environmental harm. Despite its alternative origins, SAF remains fully compatible with existing aircraft technology, allowing for seamless integration into the current infrastructure.

Beyond the environmental benefits, SAF offers socioeconomic advantages. Its geographically dispersed production utilizes diverse feedstocks, potentially creating new jobs. This is particularly promising for developing nations with abundant waste or marginal land unsuitable for food production but ideal for cultivating SAF feedstock, without negatively affecting their ability of local food production.

In the United States, cultivating biomass crops for SAF production provides farmers with additional income streams during off-seasons and offers agricultural benefits such as reduced nutrient losses and improved soil quality. Furthermore, biomass crops can contribute to erosion control, enhanced biodiversity, improved water quality and quantity, and soil carbon sequestration, providing both on-farm and broader environmental benefits.

Production of SAF from wet waste streams like manure and sewage sludge reduces pollution in watersheds and prevents the release of methane, a potent greenhouse gas, into the atmosphere.

An Airbus A320 was refuelled with biofuel in 2011.

Many types of SAF have lower aromatic content, enabling cleaner combustion in aircraft engines. This reduces emissions of harmful compounds around airports during takeoff and landing. Additionally, lower aromatic content translates to decreased contrail formation, contributing to climate change.

Beyond Offsetting: Why Sustainable Aviation Fuel Needs to Be the Future of Air Travel

While SAF presents a promising path toward a greener future for air travel, challenges persist. Production costs currently exceed those of traditional jet fuel, largely due to the nascent industry and intricate production processes. Continued research and development are essential to reduce costs and make SAF a more affordable and accessible choice for airlines. Scaling up production to meet global demand necessitates substantial investment and supportive policies, such as incentives and regulations that encourage SAF adoption.

Fossil fuels remain the aviation industry’s primary power source, but carbon offsetting falls short as a long-term solution for curbing emissions. A critical shift away from jet fuel dependence is imperative. However, transitioning to SAF comes with its own set of hurdles.

In 2019, United Airlines purchased up to 10 million US gallons (38,000 m3) of SAF from World Energy

Used cooking oil, a key ingredient for both road biofuels and cost-effective HEFA-processed SAF, could become scarce as airlines increase their demand. This potential scarcity raises concerns about limited biofuel access for other sectors beyond 2030.

Logistical challenges currently exist in Europe, where major airports require multiple low-volume SAF deliveries, negating some environmental benefits. Additionally, regulations restrict airlines from blending SAF with conventional jet fuel at a maximum of 50%. Cost pressures often lead airlines to use even smaller quantities (0.5-1%).

Currently, Neste, ENI, and BP dominate European SAF production. Neste may need to increase its ongoing capacity expansion to meet total demand. While new players like Shell entering the market in 2024 offer a glimmer of hope, cost reduction ultimately hinges on increased competition and the development of more efficient production methods. The high cost of SAF, currently accounting for 25% of airline operating expenses, remains a significant barrier to widespread adoption. Technological advancements and a more competitive landscape are crucial to driving down these costs in the future.

US Marine Corps AV-8B Harrier II test flight using a 50–50 biofuel blend in 2011

Focus on Future Potential

However, the use of SAF is increasing in the aviation industry. Increased awareness and commitment to sustainability goals among airlines, governments, and consumers are also driving demand for greener aviation solutions, compelling the companies to opt for SAF over Jet fuels. SAF will play a crucial role in reducing aviation’s environmental impact and helping achieve global carbon reduction targets as the industry evolves.

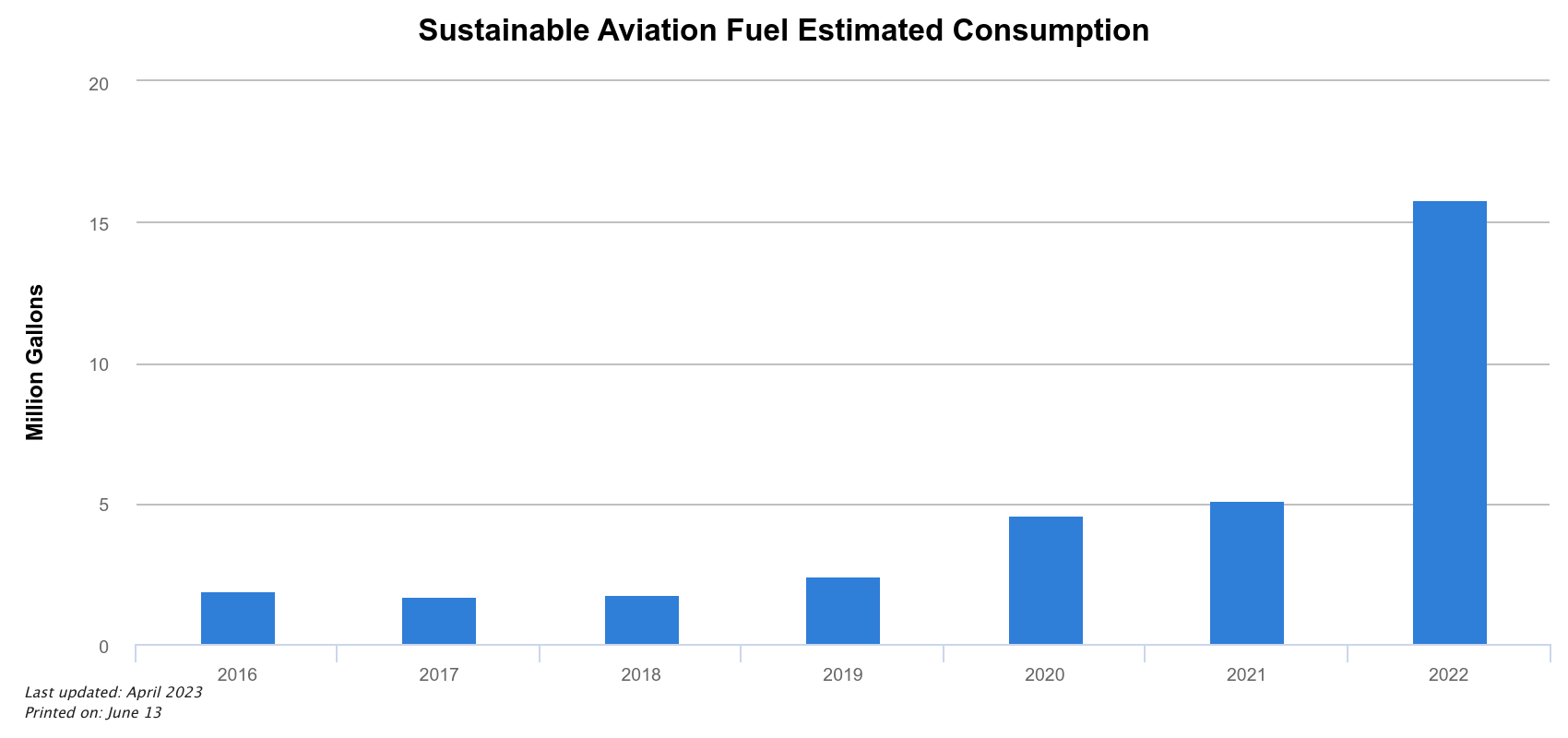

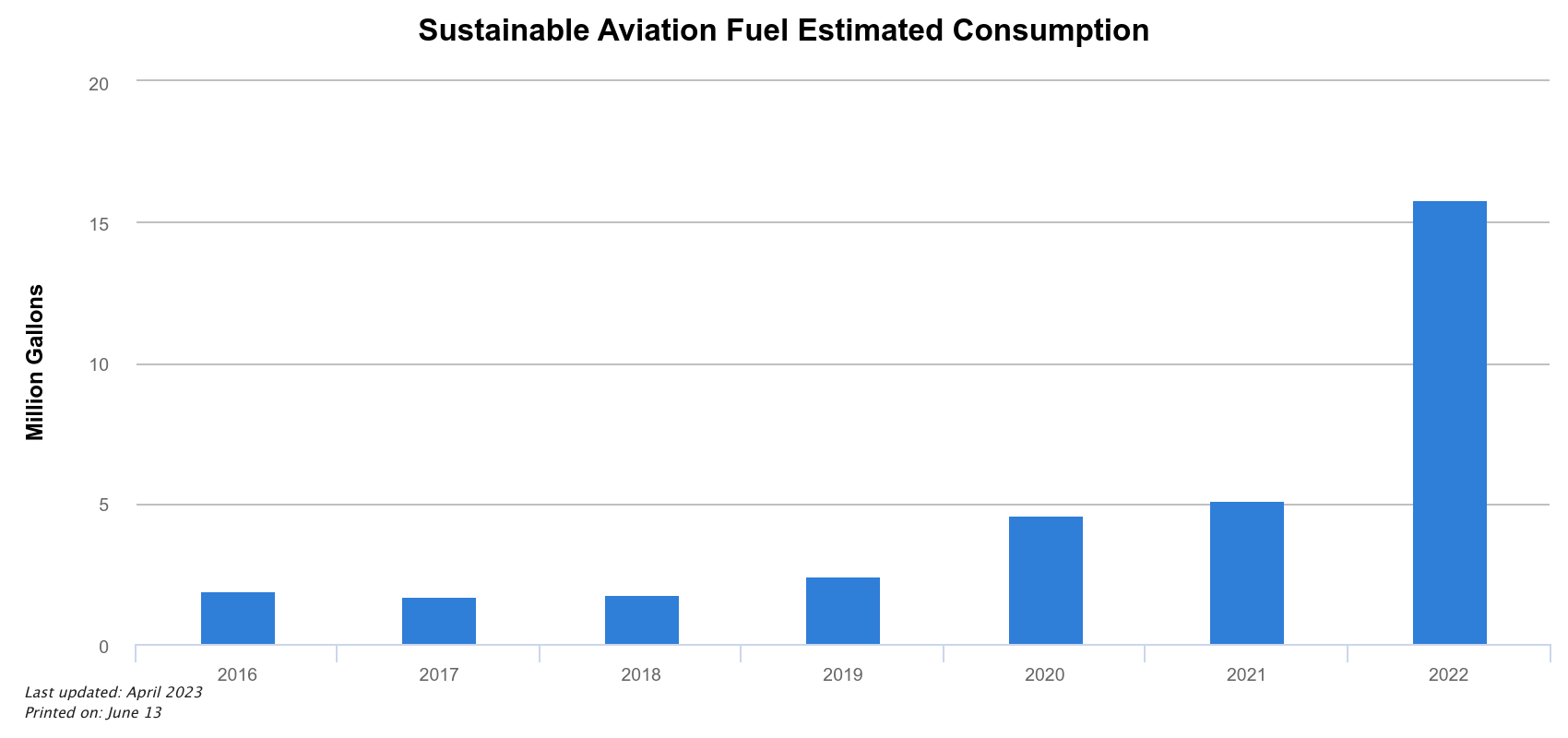

Fueled by the anticipated expansion of domestic production capacity and airlines securing off-take agreements with existing and planned SAF producers. Data from the U.S. Environmental Protection Agency’s (EPA) Renewable Fuel Standard program, which tracks the consumption of novel biofuels like SAF, reflects this upward trend. According to the EPA data, SAF consumption rose from approximately 5 million gallons in 2021 to 15.84 million gallons in 2022, with a further increase to 24.5 million gallons in 2023.

The European Union (EU) is proposing a mandate requiring airlines to blend jet fuel with SAF. This policy will significantly stimulate demand for SAF. To achieve the ambitious yet attainable goal of 5% SAF usage by 2030, production must surge from 0.24 million tonnes to 2.3 million tonnes. Existing producers are already scaling up operations, and new companies are entering the market. The increased production of SAF expects to rely primarily on used cooking oil and other sustainable feedstocks. While forecasts for 2040 and 2050 are less certain, the EU anticipates that total jet fuel demand will remain stable, but the proportion of SAF will need to rise substantially. Estimates suggest SAF usage could reach 14.8 million tonnes by 2040 and 28.6 million tonnes by 2050.

Biofuel’s importance extends to other forms of transportation as well- France’s Régiolis train runs on biodiesel.

In Conclusion

The aviation industry grapples with a critical challenge: reconciling its role in global connectivity with the consequences of carbon emissions. SAF emerges as a promising solution, offering a significant reduction in lifecycle greenhouse gas emissions compared to conventional jet fuel. This paves the way for a more environmentally responsible future for air travel.

Challenges persist, including production costs, scaling up production capacity, and ensuring a sustainable feedstock supply. However, a positive sign lies in the rising demand for SAF from airlines, governments, and environmentally conscious consumers. Technological advancements, supportive policies, and a burgeoning SAF market hold the key to overcoming these hurdles.

As SAF production scales up and costs decrease, widespread adoption becomes a more attainable objective. The aviation industry has embarked on the journey towards a sustainable future, and SAF is the fuel propelling it forward.